Polymer Blending Equipment

Affordable Asphalt Polymer Blending Equipment

American Built - Available Worldwide

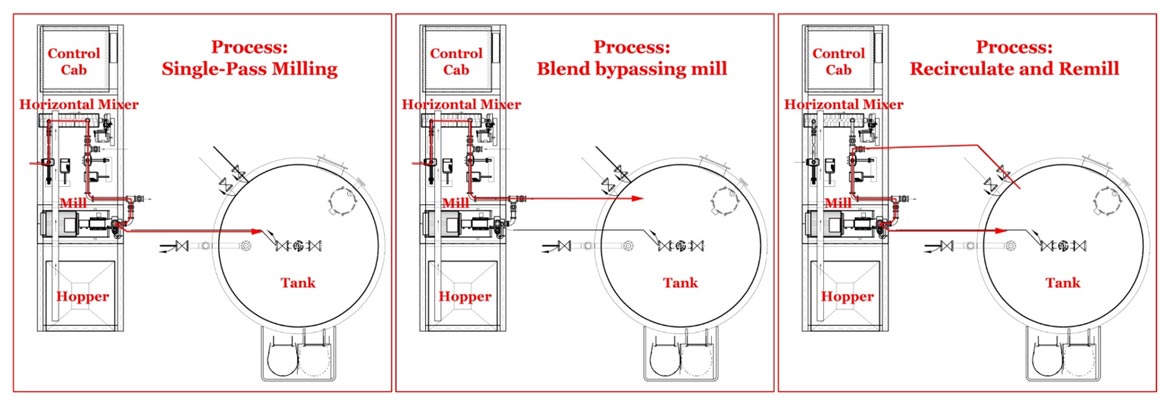

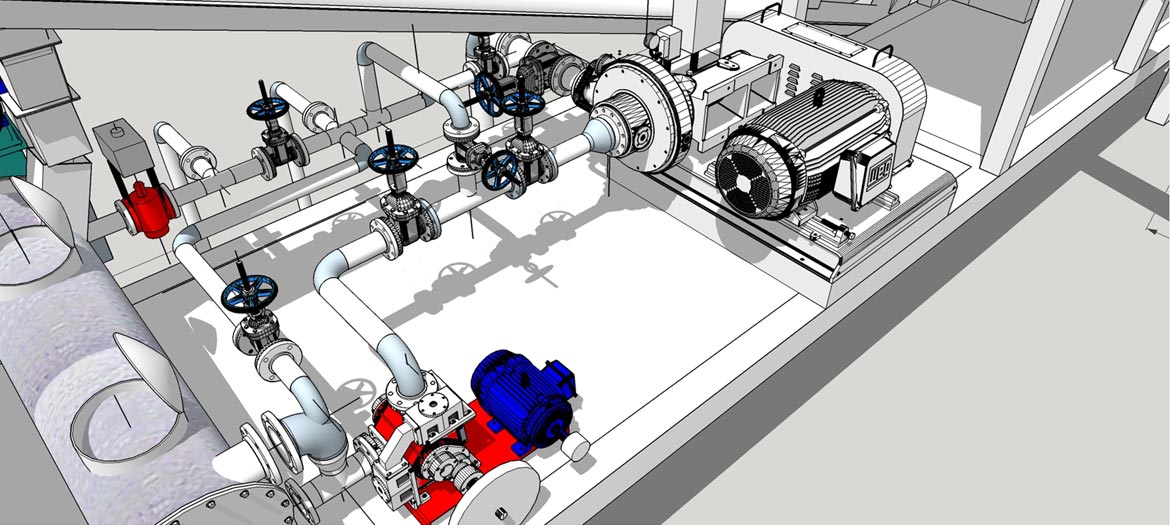

If you are currently producing PMA (polymer-modified asphalt), D&H would like to help you produce faster and more efficiently. Rather than milling and remilling over several passes, our process offers a solution that provides proven inline mixing and one-pass milling capabilities. Our years of experience in building asphalt blending/modifying equipment helped us design this process for blending and milling polymers into asphalt.

D&H can custom build polymer plants to your specific application with flow rates ranging from 10 TPH to 60+ TPH of concentrated PMA binder production. Multiple configurations including skid-mounted models for terminal blending, containerized models to allow for economical ocean shipping, and portable trailer models for blending on-site by contractors or for use at multiple terminals.

Advantages

- Capability to using one plant to produce either polymer; modified asphalt or asphalt rubber

- Greatly reduced digestion time when producing polymer modified asphalt

- D&H Horizontal Mixing Chamber (learn more about this HERE)

- Capability to refill hoppers without the need to stop blending process

- Operations can be run with as little as a two-man crew (operator and groundsman)100% manual backup controls for operation with remote access to PLC

- Capability to precisely meter liquid additives into blending process

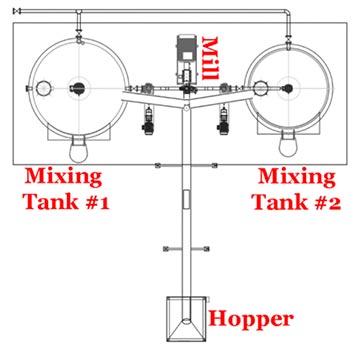

"Traditional" Polymer Milling

Disadvantages

- Batch system setup slows production capability

- Longer digestion time

- When the polymer has time to soak in the mixing tank before going to the mill, it becomes glue-like and doesn’t mill as efficiently

- Because it doesn’t mill as efficiently, it requires multiple passes through the mill, using more time, energy costs, and putting unnecessary runtime hours on the mill equipment

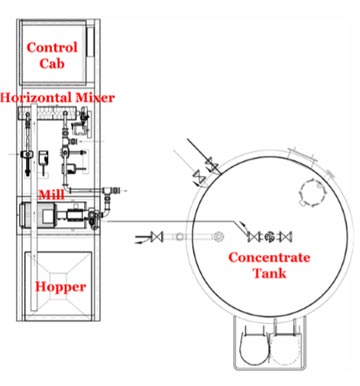

D&H Polymer Milling

Advantages

- Continuous one-pass inline blending capability

- Reduced digestion time

- Polymer is forced through the mill seconds after it combines with the liquid asphalt

- Polymer has greater tendency to shatter when it hits the mill since it hasn’t had time to become “glue-like”

- German-manufactured high shear mill

- Ability to expand production by configuring multiple concentrate and letdown tanks to offering the highest production rate

- Advanced automated control system and reporting capabilities

The Complete D&H Polymer Process