Asphalt Rubber Blending Equipment

Leading Edge Asphalt/Rubber Blending

American Built - Available Worldwide

For asphalt rubber / rubberized asphalt, D&H has been the worldwide leader in producing the top-of-the-line plants for incorporating ground tire rubber into liquid bitumen. D&H Equipment stands apart from the competition by utilizing our decades of experience in both producing asphalt rubber as well as manufacturing the specialized blending equipment.

Our plants has proven the most reliable and dependable solution for the preferred “wet-process” of rubber blending with many advantages over the competition. Whether they are completely new to rubberized asphalt or a seasoned asphalt rubber expert, our plants continue to impress and exceed our customers’ expectations.

Our Rubber Blending Plants Have Been Used for Producing:

- ASTM Asphalt Rubber

- CalTrans Spec Asphalt Rubber

- PG-graded rubberized asphalt

- Rubber/Polymer Hybrid Blends

- Warm mix rubberized asphalt

- “Engineered” Rubberized Asphalt

"D&H can custom-build rubber blending plants to your specific application with flow rates ranging from 10 TPH to 60+ TPH of binder production."

"We also offer multiple configurations including portable trailer-mounted plants for contractors, stationary skid-mounted plants for terminals, and containerized units for international customers."

60+TPH BLENDING & 50+0F HEAT RISE

"This Is By Far, The Most impressive Blending Plant I've Ever Witnessed" - Marc Bertsch

Advantages

PLC Controls

- RELIABILITY - Greater reliability than PC systems due to embedded real-time operating system (RTOS) with a dedicated processor

- ROBUSTNESS - Standard PLCs contain no moving parts so they can withstand harsh environments for millions of cycles; standard PCs contain moving parts such as fans or hard disk drives and are less suitable for environments with high vibration levels unless fitted with additional options including solid-state had drives, fan-less cooling, and in-cabinet mounting

- SERVICEABILITY - PLC external devices can be replaced with ease while the system is in operation. PLCs compact modular design makes replacing the actual controller an easier job, saving cost by reducing downtime. PLCs are easier to implement “exact-copy” replacements since the hardware and firmware doesn’t change as rapidly as PCs

- SECURITY – PLC is less exposed to unauthorized access from the outside world due to its dedicated operating system

Blending Program

D&H’s proprietary blending software was developed from the ground-up specifically for managing blending operations. It was developed with input by experienced operators to be simple and easy to understand and easy to use. It is backed by decades of experience and feedback. Printouts of blending plant operations are also available.

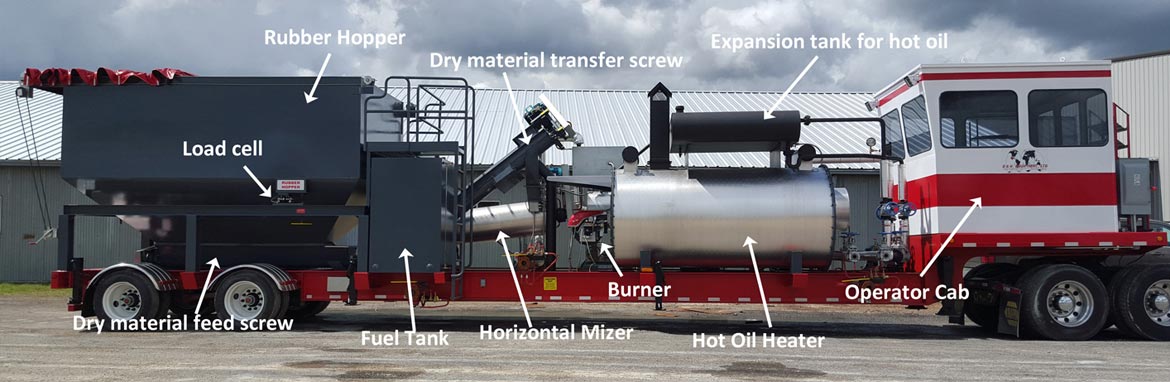

Operator Cabin

A spacious operator control room houses the controls in a climate-controlled environment with an industrial ductless air conditioning unit. Tinted safety glass windows allow the operator a 360° view of blending and plant operations.

Proprietary Horizontal Mixing Chamber

- Guaranteed 100% coverage and dispersion of dry materials into asphalt

- Greatly reduced maintenance and repair

- Reduced volume of mixer allows for greater accuracy when blending smaller batches, but is still capable of blending at greater production rates up to 45 tons/hr

- Pressure-fed system vs relying on a gravity overflow allows for greater control and safety because the unit is more controlled and contained

- Dual redundant high level safety devices with overflow piping included

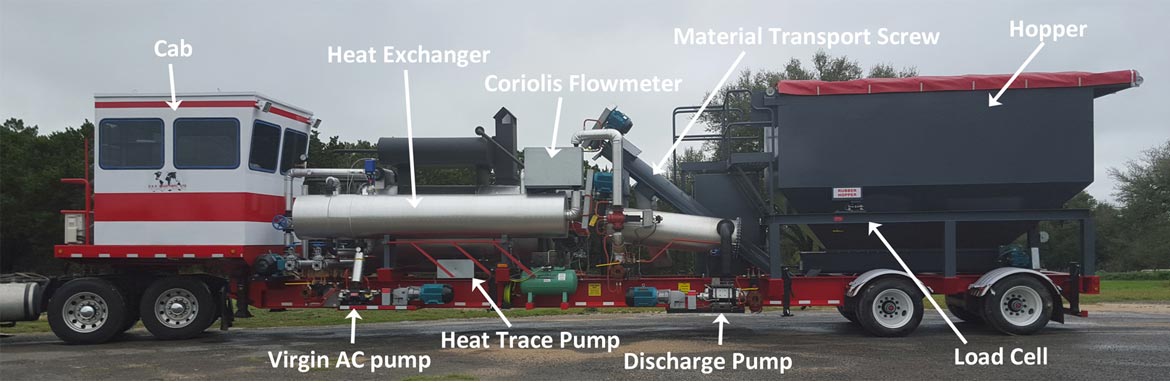

Pumps

D&H utilizes Bearcat pumps which have been specifically designed for handling highly-modified asphalts including asphalt rubber and polymer modified asphalts. Bearcat pumps can also be rebuilt at their factory and the company offers a great pump exchange program for service.

Hoppers and Dry Material Metering

- ACCURACY – Utilizes either loss-in-weight hoppers mounted on load cells or weighbridge feeding systems to improve accuracy and repeatability over volumetric or solid-impact flow systems.

- SIZE - Hoppers are much larger than our competitors allowing you to blend more without the need to continually reload the hopper(s).

- BAG CUTTERS – Supersack bag cutters on top of the hoppers allow for faster, safer, and easier unloading of material.

- HOPPER RELOADING - Blending plant operators are able to reload hoppers on-the-fly (without the need to stop blending) by use of our automated blending plant software

- MATERIAL FEED – Uses a feed screw which travels the length of the hopper bottom. The greater surface area of the feed screw is more effective at ensuring a reliable dry material feed from the hopper.